Choosing the right shale shaker screen size is very important for your work. If you pick the wrong screen size, you can have many problems:

You might lose costly drilling fluids.

Pumps can break too soon.

Equipment may not last as long.

Drilling can slow down.

Other solids control equipment can get too full.

You should think about drilling fluid properties like viscosity and specific gravity. You also need to know the size of the solids you expect. The correct shale shaker screen size helps you work better, spend less money, and keep your shale shaker and other equipment safe.

Key Takeaways

Picking the right shale shaker screen size helps your equipment last longer. It also saves money and keeps drilling working well. Mesh size and API numbers help you choose screens that catch the right solids. They also help keep your drilling fluid clean. Match your screen to your drilling fluid’s thickness. Also, think about the size of solids you expect. This gives you the best results. Use strong screen materials and set your shaker the right way. This helps your screens last longer and makes drilling better. Always ask experts for help and check your screens often. This helps you avoid problems and get the best results.

Shale Shaker Screens Overview

Shale Shaker Screens Role

You use shale shaker screens first in your drilling mud system. These screens sit on the shale shaker and help remove bad solids from your drilling fluids. When drilling starts, the shale shaker screens catch cuttings bigger than 100 microns. This keeps your pumps and other equipment safe. You keep your drilling fluid clean and good quality.

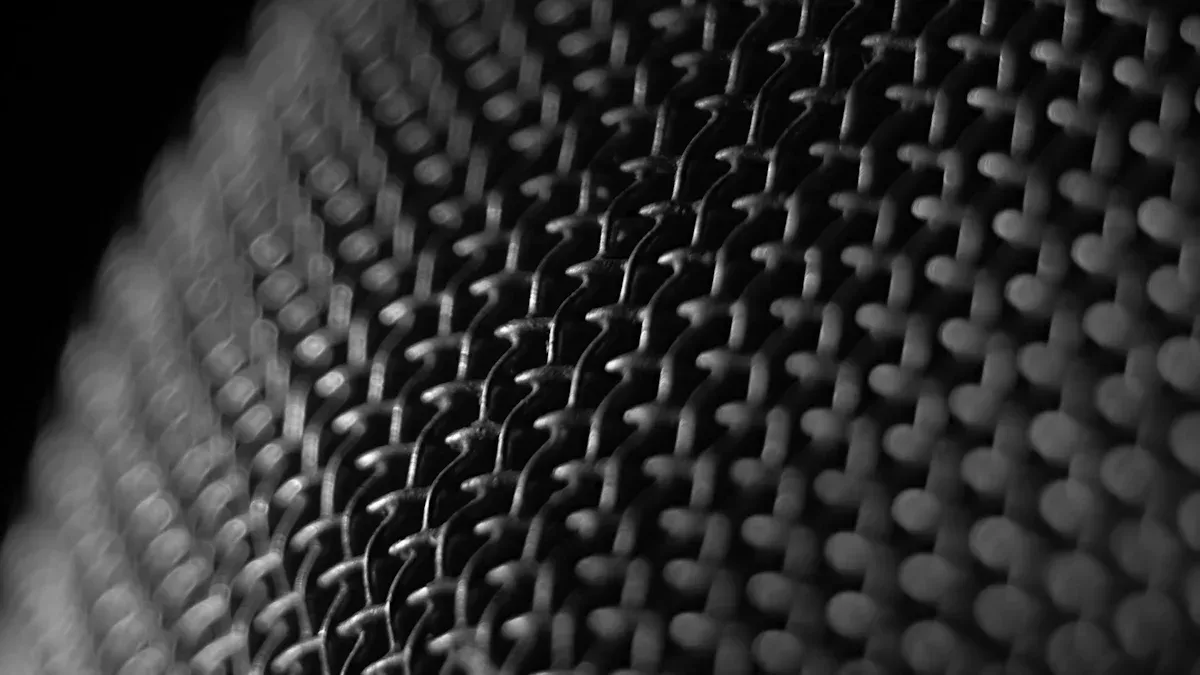

Shale shaker screens have layers of mesh cloth and strong stainless steel wire mesh. This design helps trap smaller pieces and makes the screens last longer. You get screens that follow API 13C standards, so they work well and last a long time.

Tip: Good shale shaker screens stop fluid loss by shaking thin layers of drilling fluid. You dry the cuttings faster and make solids control better.

Here are some main jobs of shale shaker screens:

They filter drilling fluids and block bigger solids.

They take out bad solids, so fluid works better.

They let the shaker handle more by making the screening area bigger.

They sort solids by size, usually catching cuttings over 100 microns.

Why Screen Size Matters

You must pick the right screen size for your shale shaker. The size of the holes in the shale shaker screens decides which pieces stay out of your drilling fluid. Smaller mesh sizes (higher mesh numbers) mean the screens are finer. These screens have tinier holes, so they catch more small pieces.

If you change from a 10 mesh to a 60 mesh screen, you let much fewer particles through—over 450 times less. You get better solids removal and protect your equipment. People in the field see that using finer scalping screens above main screens can cut down wear on the main screens by about 90%. You also take away up to 250 times more drilled rock per screen.

Note: The mesh number is not the only thing that matters. The shape and thickness of the wire and the size of the holes are more important for solids control.

Taking care of your shale shaker screens helps you get the best results. You can fix worn screens and use double deck shakers to remove more solids and make screens last longer. When you pick the right screen size for your drilling, your work goes smoothly and well.

Mesh Size & API Number

Mesh Size Basics

It is important to know about mesh sizes when using shale shaker screens. Mesh size tells you how many holes are in one inch of the screen. If the mesh number is higher, the holes are smaller. This means the screen can catch smaller pieces. For example, a 20 mesh screen has bigger holes than a 100 mesh screen. You pick different mesh sizes based on what solids you want to take out of your drilling fluid.

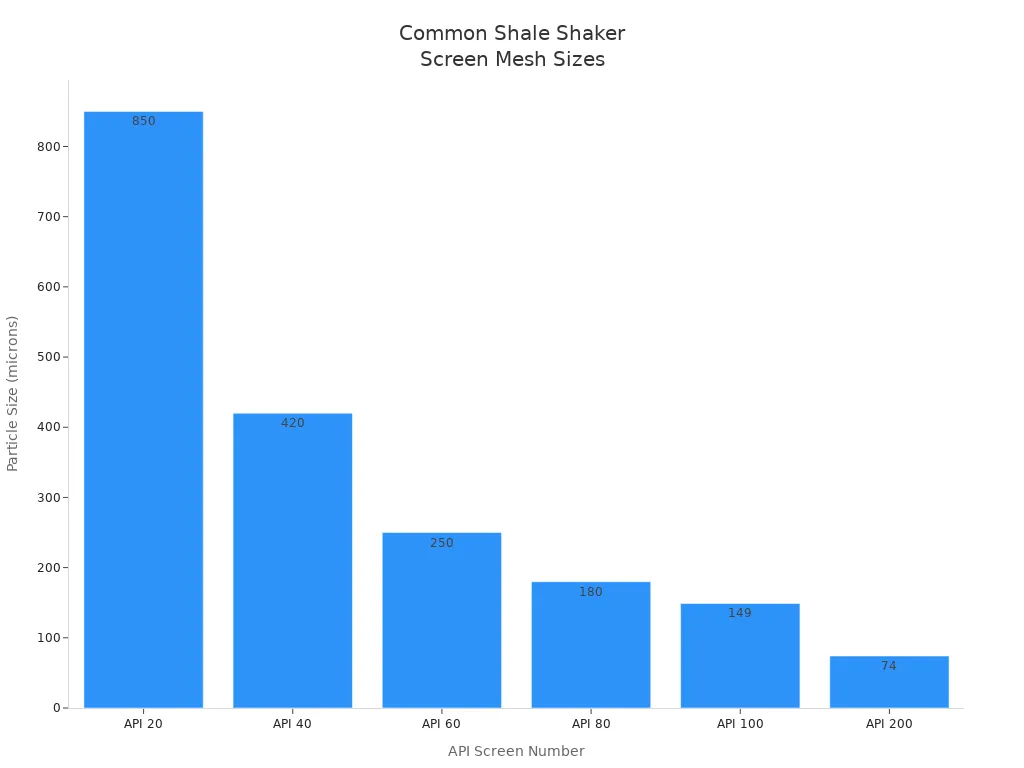

In oil and gas drilling, people use mesh sizes from coarse to fine. The table below shows common mesh sizes and the size of particles they catch:

API Screen Number | Approximate Particle Size Range (microns) |

API 20 | ~850 microns |

API 40 | ~420 microns |

API 60 | ~250 microns |

API 80 | ~180 microns |

API 100 | ~149 microns |

API 200 | ~74 microns |

You choose mesh sizes by thinking about the solids you expect in your drilling job. Picking the right mesh helps you get rid of bad solids but keep the good drilling fluid.

API Number Guide

API numbers help you compare shale shaker screens in a standard way. The American Petroleum Institute made a system called API RP 13C. This system uses something called the D100 cut point. The D100 cut point is the size where all the sample stays on the screen. You find this by doing a special test with Aluminum Oxide and a stack of sieves.

The API number is now used instead of old mesh count terms. It gives you a clear and easy way to pick screens. This makes it less confusing to choose the right mesh.

API RP 13C is now used around the world as ISO 13501. This means you can compare screens from different companies using the same rules. You can trust the API number to help you pick the right mesh for any drilling job.

Particle Removal & D50 Cut Point

When you use shale shaker screens, you want to know how well they take out solids. The D50 cut point tells you the size where half the solids go through and half stay on top. This number shows the middle size that the screen separates.

If the screen has a sharp D50 cut point, it removes more unwanted solids. This keeps your drilling fluid cleaner. How well the screen works depends on its design, the mesh size, and the drilling fluid. You should pick shale shaker screens with a sharp D50 cut point and steady performance. This helps you get the best results and keeps your drilling running well.

Shaker Screen Selection Factors

Drilling Fluid Properties

You need to check your drilling fluid before picking a shale shaker screen. The thickness and weight of the fluid change how the screen works. If your fluid is thick, thinner wire screens help separate solids better and keep the fluid moving. If your fluid is light, like water-based mud, thicker wire screens last longer and still work well.

Thick fluids: Use thinner wire screens for better flow.

Light fluids: Pick thicker wire screens for longer use.

Always match the API separation point to your fluid for the best results and to save money.

You should also change your shale shaker settings. For big, heavy rock pieces, use more force and a slower shake. For small, weak pieces, use less force and a faster shake. These changes help your screens work better and last longer.

Expected Particle Size

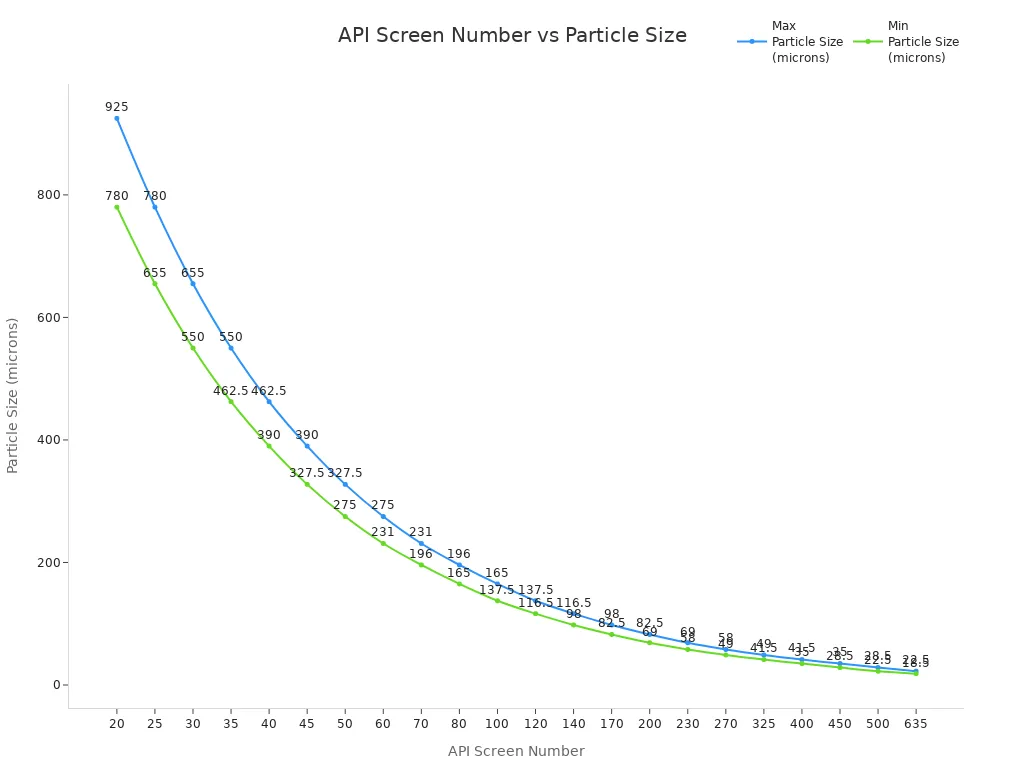

You need to know the size of the solids in your drilling fluid. This helps you pick the right mesh size and API number for your screens. If you have big cuttings, use a screen with bigger holes. For tiny solids, use a screen with smaller holes. The table below shows common API screen numbers and the sizes they catch:

API Screen Number | Approximate Particle Size Range (Microns) |

20 | 780 to 925 |

40 | 390 to 462.5 |

60 | 231 to 275 |

100 | 137.5 to 165 |

200 | 69 to 82.5 |

325 | 41.5 to 49 |

When the API number goes up, the screen catches smaller pieces. This helps you take out more unwanted solids and keep your fluid clean.

![Line chart showing the decrease in particle size range as API screen number increases for drilling fluid mesh screens.]()

Shaker Screen Material & Design

Feature | Composite Shaker Screens | Stainless Steel Shaker Screens |

Weight | Lighter, helps the shaker work better | Heavier, may not separate fluid as well |

Manufacturing Efficiency | Easier and cheaper to make | Harder to make, may cost more |

Durability | Good mix of lasting long and saving money | Very strong and does not rust, good for tough jobs |

Frame Deformation | May bend during high heat, but usually stays even | Not known to bend, stays strong |

Performance Impact | Lighter screens help fluid move faster | Strong but heavy, may change how shaker moves |

Maintenance & Longevity | New types last longer | Known to last a long time and not rust |

Shale Shaker Capacity

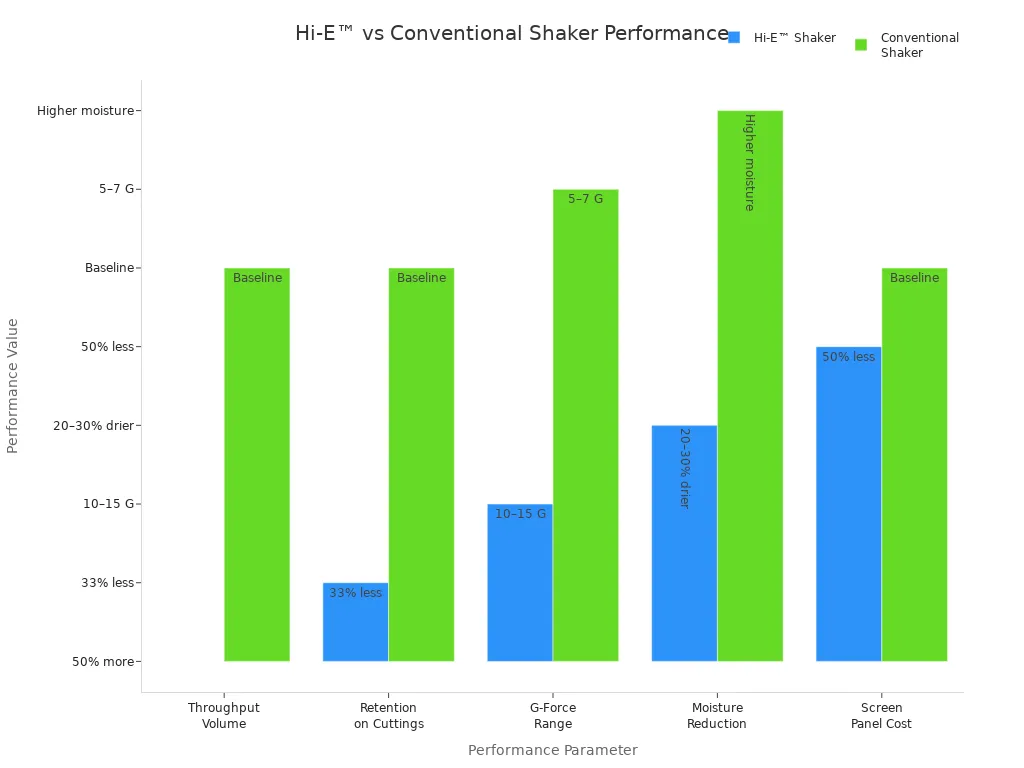

Efficiency vs. Cost

![Bar chart comparing Hi-E™ and conventional shaker performance across key technical parameters]()

The material and design of your screens are important. Stainless steel screens last longer and do not rust, which is good for hard jobs. Composite screens are lighter and cost less, but still last a long time. Picking the right material helps you control solids, protect your equipment, and drill better.

Some new shale shakers, like the Double/Triple Deck Shaker from Xilong Machinery, use screens you can swap out easily. These designs give you more screen space, so you remove more solids and the screens last longer. The screens are easy to change, so you spend less time fixing things and more time drilling.

Shaker capacity means how much fluid your shaker can handle. If you drill a lot, you need screens with enough open space for the fluid to pass through. This keeps the fluid moving and stops the screen from getting blocked. In these cases, you often use bigger mesh screens, like 40-60 mesh, to handle more solids and faster flow. Bigger holes help stop clogging and keep your work going.

You want most of the screen to stay wet while working. This keeps the fluid moving fast and means less fixing. Some new shakers, like those from Xilong Machinery, use strong motors and big screens to handle more fluid. These features help you move more fluid, take out more solids, and save money.

When you pick a shale shaker screen, you need to think about both how well it works and how much it costs. Good screens may cost more at first, but they last longer and work better. This means you do not have to change them as often and you save time. Picking the right screen size for your fluid and shaker can save you a lot of money on each well.

New features, like screens you can swap and strong motors, help remove more solids and lose less fluid. These upgrades help you meet industry rules and lower your costs. By picking the right screens and using new equipment, you get better solids control and drill faster.

Shale Shaker Screen Selection Guide

Assess Drilling Conditions

When selecting a shale shaker screen, you need to start by looking at your drilling conditions. Every drilling site is different. The environment and geology can change what works best. Here are some important factors you should check:

The location and type of rock you drill through. What works in one place may not work in another.

The properties of your drilling fluid, such as thickness, type, and what you add to it.

The temperature at your site and how fast you drill.

How the solids and liquids in your well interact.

The size of the hole and if there is any erosion.

Advice from local experts or solids control advisors.

Tip: Standard charts for selecting a shale shaker screen may not always work. Local conditions matter most. Always check what has worked in your area before.

Match Screen Size to Needs

You need to match the screen size to your operation’s needs. This step helps you get the best results from your solids control system. Start by thinking about the type of drilling you do and what you want to achieve. Use the following steps to guide you:

Understand your drilling project and what you need from your shaker screen.

Choose the mesh size based on your drilling fluid. Thicker or heavier fluids need smaller mesh sizes to catch finer solids.

Pick the right screen panel. You can use single, double, or triple layers, depending on how much fluid and solids you have.

Select the screen material. Stainless steel works well for tough jobs and lasts longer.

Think about how the screen will perform. Look at the cut point, how easily fluid passes through, the angle of your shaker, and how much it vibrates.

Balance your choice. Finer mesh sizes catch more solids but may slow down fluid flow. You need to find the right mix for your job.

Mesh Size | Typical Use Case |

20 | Separation of coarser solids |

30 | Suitable for lighter solids |

40 | Ideal for various mud types |

50 | Best for fine drilling applications |

Modern shale shakers, like those from Xilong Machinery, let you adjust vibration and deck angle. You can fine-tune your screen’s performance based on mud thickness and flow rate. Smart controls and real-time monitoring help you make quick changes, so your screen always matches your drilling needs.

Consult Experts & Suppliers

You should always talk to experts and trusted suppliers when selecting a shale shaker screen. They use many factors to help you choose the best option:

Mesh size, which tells you what size particles the screen can separate.

The type of drilling and the kind of rock you drill through.

The properties of your drilling fluid, such as how thick or heavy it is.

The performance you need, like the API number and cut point.

If the screen fits your shaker and meets industry standards.

The volume of fluid and solids you expect.

The design of the screen panel, such as single, double, or triple layers.

How strong and long-lasting the screen material is.

How well the screen lets fluid pass through.

When you contact a supplier, give them as much information as possible:

The size and type of solids you want to remove.

The type and size of the screen you need.

The model of your drilling equipment.

The results you want, such as how clean you want your fluid.

How long you want the screen to last and how much fluid it should handle.

Any special needs, like resistance to clogging or easy cleaning.

Note: The more details you provide, the better the supplier can match the right shaker screen to your operation. Xilong Machinery can help you with tailored recommendations and product selection for your specific needs.

Avoid Common Mistakes

Many people make mistakes when selecting a shale shaker screen. You can avoid these problems by following some simple rules:

Do not pick a mesh size that does not match the size of the solids you want to remove. This can cause the screen to clog or let too many solids through.

Always consider the properties of your drilling fluid. If you ignore viscosity or density, your screen may not work well.

Pay attention to screen design and material. Weak screens or the wrong type can wear out fast or fail.

Use the right screen configuration for your shaker and your job.

Clean your screens often. Use mechanical or pneumatic systems to keep them clear.

Adjust your shaker settings to help remove trapped solids.

Keep your drilling fluid in good condition to stop the screen from blinding.

Check and maintain your screens regularly.

Train your team so everyone knows how to keep the screens working well.

Alert: Poor screen selection can lead to lost drilling fluids, broken pumps, shorter equipment life, and slower drilling. Always take time to choose the right screen and keep it in good shape.

Troubleshooting Shale Shaker Screens

Screen Wear Signs

You need to watch for signs that your screens are wearing out. Worn screens can hurt your drilling performance and cause problems. Look for these common signs:

Discoloration on the screen surface

Holes or cracks in the mesh

Reduced mesh size or broken wires

These signs mean the screen cannot filter solids well. Wear often comes from debris rubbing against the mesh, harsh fluids, or repeated shaking. If you see these problems, replace the screen soon. Regular cleaning and inspection help you catch wear early and keep your operation running smoothly.

Tip: If you notice pressure changes or more solids in your fluid, check your screens for damage right away.

Performance Issues

When your screens do not work as expected, you can follow a few steps to find and fix the problem:

Check the main power supply and make sure it is on.

Look at isolators or switches and set them correctly.

Inspect all power connections and wiring for damage or loose parts.

Examine fuses or circuit breakers and replace or reset them if needed.

Reset thermal overload settings if the motor does not turn.

Inspect the motor for damage or overheating.

Test motor windings with a multimeter.

If the problem continues, call a qualified technician.

You should also check the mesh size, shaker design, and vibration motor. Make sure the tensioning system is tight and adjust the deck angle if needed. These steps help you improve shaker performance and avoid downtime.

Maintenance Tips

Good maintenance keeps your screens working longer and saves money. Try these tips:

Clean screens after each use to remove solids and prevent abrasion.

Store clean screens in a dry, safe place. Use racks for used screens and mark them with hours run.

Inspect the screen surface and shaker parts before drilling.

Adjust the bed angle based on flow rate. Use a higher angle for high flow and a lower angle when flow is steady.

Use less fine screens during top hole drilling to reduce early wear.

Replace damaged screens quickly to keep your system efficient.

Regular care and the right settings help you get the most from your screens and support strong drilling performance.

To pick the best screen size, do these things: First, think about what your drilling job needs and how your fluid acts. Next, talk to experts who can give you special advice for your job. Then, look at different screen types and materials to see which ones last longer and cost less. After that, try out the screens while drilling to see how well they work.

Checking your screens often and getting help from experts can help you spend less and work better. You can ask Xilong Machinery for expert help and new ideas.

FAQ

What is the difference between mesh size and API number?

Mesh size tells you how many holes are in one inch of screen. API number is a standard that helps you compare screens from different companies. You use API numbers to pick the right screen for your drilling job.

How often should I replace shale shaker screens?

You should check your screens every day. Replace them if you see holes, tears, or worn spots. Regular checks help you avoid equipment damage and keep your drilling fluid clean.

Can I use the same screen size for all drilling fluids?

No, you should match the screen size to your drilling fluid type. Thick fluids need finer screens. Thin fluids work better with coarser screens. Always adjust your screen choice for the best results.

What are signs that my screen is not working well?

Look for more solids in your drilling fluid, slower fluid flow, or pressure changes. You may also see damaged mesh or more fluid loss. These signs mean you should check or replace your screen.

How do I choose the right screen for my shaker?

Start by knowing your drilling conditions and fluid properties. Give this information to your supplier. You can also ask Xilong Machinery for expert advice and tailored recommendations for your operation.