You will see five main types of shale shaker screens used today:

Hook Strip Flat Screen

Pyramid Screen

Steel Frame Screen

Polyurethane Frame Screen

Composite Screen

Shale shaker screens are very important in solids control. They help by separating drilling solids from fluids. This helps your equipment work well and last longer. Drilling is getting more advanced every year. You need better equipment like the Double/Triple Deck Shaker from Shandong Xilong Machinery Equipment Co., Ltd. This shaker uses new screen technology to work better and make solids control easier.

Key Takeaways

Shale shaker screens take solids out of drilling fluid. This keeps equipment safe and helps drilling work well.

There are five main screen types. These are Hook Strip Flat, Pyramid, Steel Frame, Polyurethane Frame, and Composite. Each type has its own strengths for different drilling jobs.

Picking the right screen type and mesh size helps remove solids better. It also saves money and makes screens last longer.

Using modular screens and quick-change systems makes maintenance faster. This also cuts down on downtime at drilling sites.

Checking screens often and taking care of them keeps drilling working well. It also protects your equipment.

Shale Shaker Overview

What Is a Shale Shaker

A shale shaker is very important on a drilling site. It helps separate big pieces from the drilling fluid. The shaker uses vibration to move the screen. When drilling mud goes over the screen, small bits and liquid fall through. Large pieces stay on top and slide off the end. This keeps the drilling fluid clean so you can use it again. Clean fluid helps protect your equipment. It also makes drilling go smoothly. The shale shaker is the first part of the solids control system. It is needed for oil and gas drilling.

Tip: Picking the right shaker screen helps you get rid of more cuttings and save money on fluid.

Importance in Drilling

You need a good shale shaker for better drilling. The shaker lowers the solids in the drilling mud. This means pumps and other tools last longer. Removing cuttings early helps protect other solids control equipment. It also keeps your work going without stopping. Clean fluid lets you drill deeper and faster. This saves time and money.

Advanced shakers like the Double/Triple Deck Shaker from Shandong Xilong Machinery Equipment Co., Ltd. make solids control better. These shakers handle more drilling mud in less space than single deck shakers. You can use different screens on each deck. This lets you change how you separate solids for your job. Double deck shakers have twice the screen area. You catch more cuttings and get drier waste. This means less trash and better fluid recovery.

Feature | Benefit |

Large screen area | Separates solids better |

Sequential filtration | Removes smaller bits and makes cuttings drier |

Modular screen panels | Easy to change for different drilling jobs |

Modern shakers help you control solids and follow rules for the environment. With good equipment, your drilling is safe, works well, and costs less.

Shale Shaker Types

There are five main shale shaker types used in drilling. Each screen type has its own special benefits. These screens help control solids and manage fluids. Some shakers have more than one deck. You can use different screens on each deck. This makes the shaker work better and easier to fix.

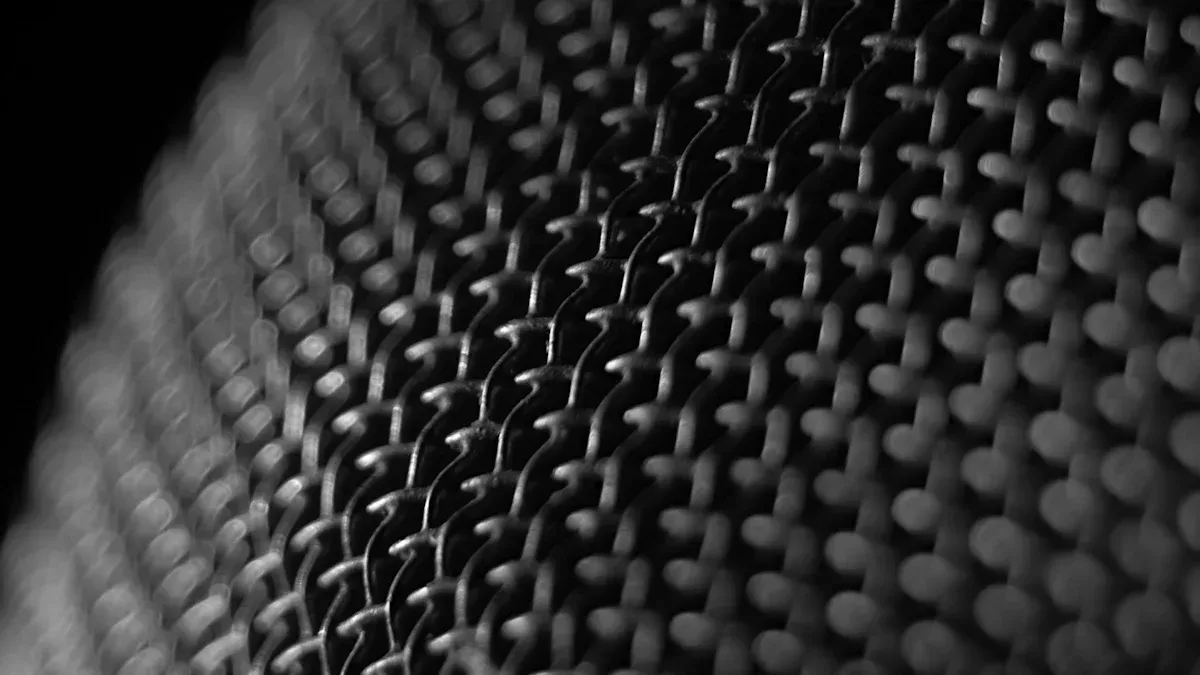

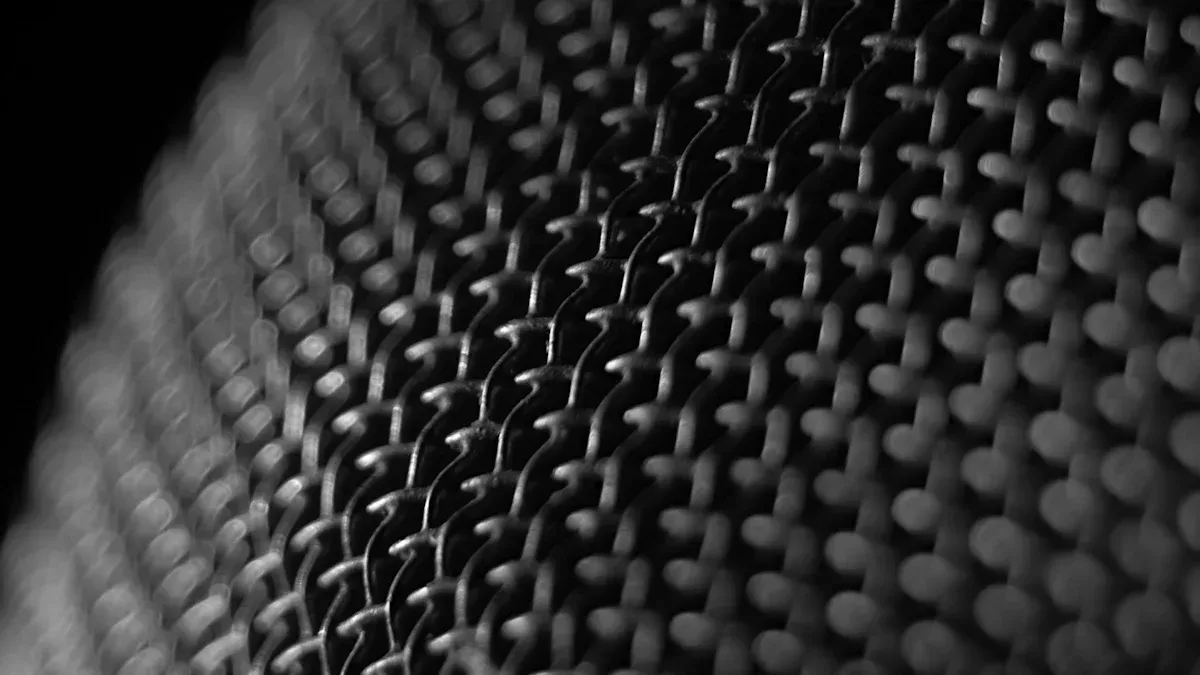

Hook Strip Flat Screen

Hook Strip Flat Screens are often used in drilling. They have one to three layers of stainless steel mesh. The mesh is stuck to a thin grid. The screen connects to the shaker deck with hookstrips and drawbars. Tensioning bolts keep the screen tight. This helps the shaker’s energy move to the screen. It makes solids separate faster and helps the screen last longer. You do not need to change screens as often. This saves money and time. Seals around the edges stop leaks. The screen fits tightly and does not move when working.

Stainless steel mesh layers make the screen strong

Hookstrip and drawbar system keeps the screen in place

Tight tension helps solids separate faster

No crown rubbers needed, so you save money

Edge seals stop leaks and keep cuttings inside

You use Hook Strip Flat Screens for easy care and good solids separation. These screens are easy to swap out if one gets damaged.

Pyramid Screen

Pyramid Screens have a wavy, three-dimensional shape. This gives you a bigger screening area. You can process more drilling fluid at once. The pyramid shape helps you get drier cuttings and lose less mud. This saves money and helps the environment. These screens have two or three layers of stainless steel mesh. A metal plate with holes makes them strong. They do not wear out fast and can handle heat and rust.

Feature | Description |

Screen Design | Pyramid shape gives more screening area |

Mesh Material | Two or three layers of stainless steel mesh |

Backing Plate | Metal plate with holes for strength |

Durability | Stands up to wear, rust, and heat |

Typical Applications | Used for oil drilling, drier cuttings, and less mud loss |

You use Pyramid Screens to catch smaller solids and save more drilling fluid. They work well in shakers with more than one deck.

Steel Frame Screen

Steel Frame Screens are very strong and last a long time. The frame is made from tough steel. It does not bend or break easily. The frame has a special coating to stop rust. Stainless steel mesh is pulled tight across the frame. Clamps and rods hold it in place. Support plates spread out the weight. This keeps the screen flat and working well. You can pick different mesh sizes and frame shapes for your job.

Strong steel frame lasts longer

Special coating stops rust

Tight mesh does not sag

Support plates spread out pressure

You can choose mesh and frame size

You use Steel Frame Screens for tough jobs and heavy materials. They are easy to change for different drilling needs.

Polyurethane Frame Screen

Polyurethane Frame Screens are tough against wear, rust, and chemicals. The screen is flexible and works with many particle sizes. Polyurethane does not need extra coatings. It lasts longer than steel mesh. These screens are best for wet jobs and removing water. Polyurethane has a strong bond, so it wears out slowly. Some screens mix materials to last longer and make less noise.

Resists wear, rust, and chemicals

Flexible design fits many particle sizes

Big open area and stops clogging

Steel wire inside makes it stronger

Soft material makes less noise

You use Polyurethane Frame Screens in hard and wet places. They last much longer than wire mesh screens. You can replace only the broken parts, which saves money.

Composite Screen

Composite Screens use many layers of stainless steel mesh and a strong polyurethane frame. These screens do not bend, dent, or rust. They have more surface area than regular screens. This lets you handle more fluid and thicker mud. The mesh is pulled tight for better separation and longer life. You can fix damaged parts with a rubber plug. This means less downtime.

Many mesh layers for better work

Polyurethane frame is strong and tough

Rubber plug system makes repairs fast

High screening power and lasts long

Cheaper to replace and easy to care for

You use Composite Screens to filter drilling mud and separate solids. They fit many shaker models and work well in modular systems.

Tip: If you use modular screens in double-deck shakers, you can mix screen types. You only need to change broken panels. This helps screens last longer and makes solids separation better for each job.

Features and Advantages

Durability

You want screens that last a long time. The best screens use strong materials for tough jobs. Most screens have stainless steel mesh. This mesh does not rust and keeps its shape. Polyurethane makes screens flexible and helps them last longer. Composite materials make screens even stronger. They also help screens last longer when you need high performance.

Stainless steel mesh is strong and does not rust.

Polyurethane mesh is flexible and resists damage.

Composite mesh mixes the best features for great results.

How long a screen lasts depends on the mesh type, drilling job, and how you use the shaker. Some screens last only 20 hours. Others can last more than 20 days. Pyramid screens often last longer. Their shape stops solids from blocking and breaking the screen. Taking care of your screens and picking the right one helps your equipment work better.

Efficiency

You need your screens to work well for smooth drilling. The design and size of screens matter a lot. Bigger screens let more fluid and solids pass through. This helps the screen clean better. Flat screens give a wide area for removing solids. Pyramid screens have a 3D shape. This shape gives more space and helps you handle more fluid.

Bigger screens remove more solids.

Pyramid mesh lets you handle more fluid and stops leaks.

The right screen design makes your shaker work better.

For best results, about 75% of the screen should be covered with drilling fluid. The other 25% should dry the solids. This balance helps your equipment work well and keeps your job running smoothly.

Replacement and Maintenance

Changing screens fast saves you time and money. The Double/Triple Deck Shaker uses screens you can change quickly. You do not need tools to swap screens. This cuts down the time you spend on repairs. You can spend more time drilling.

Quick-change screens let you swap panels fast.

No tools are needed, so fixing is easy.

Modular screens fit many shakers and keep your equipment working well.

Tip: Always look at your screens for damage. Change broken mesh right away. This keeps your shaker working and protects your drilling job.

Comparing Types

Design Differences

There are clear design differences between shale shaker screens. Each screen type has its own special structure. This changes how it works during drilling.

Hook Strip Flat Screens have a flat mesh held by hooks. The hooks are on the edges. This design is simple and works well for separating solids.

Pyramid Screens have a raised, 3D shape. This shape lets you handle more fluid. You get up to 40% more screening area than flat screens. Fluid flows better through these screens.

Steel Frame Screens use a strong steel frame with tight mesh. The frame does not bend or rust. This makes it good for hard drilling jobs.

Polyurethane Frame Screens use flexible polyurethane. This material does not wear out fast. It also resists chemicals and works with many particle sizes.

Composite Screens have many mesh layers and a tough polyurethane frame. These screens do not bend or rust. You can fix them easily with rubber plugs.

Pick the screen design that matches your drilling needs. Advanced shakers like the Double/Triple Deck Shaker let you use different screens on each deck. This helps you get the best results for every job.

Performance Factors

Performance is important when picking a shale shaker screen. You want screens that let lots of fluid pass, last long, and control solids well. The table below shows how the main types compare:

Screen Type | Construction | Cut Point Characteristics | Throughput Capacity | Screen Life & Blinding Resistance |

Hook Strip Flat | Flat mesh, hook strips | Coarse cut point | Moderate | Good, but can blind |

Pyramid | 3D raised mesh | Finer cut point | High | Long life, resists blinding |

Steel Frame | Steel frame, tight mesh | Variable | High | Very durable |

Polyurethane Frame | Polyurethane, flexible mesh | Variable | High | Excellent wear resistance |

Composite | Multi-layer mesh, PU frame | Fine cut point | High | Long life, easy repair |

Think about durability, cost, and if the screen fits your shaker. Pyramid screens cost more but work better and last longer. Steel frame screens are strong and reliable. Composite screens are easy to fix and cost less. Always pick screens that fit your shaker’s deck. This is important for advanced shakers like the Double/Triple Deck Shaker. The right screen gives you better performance and saves money.

Tip: Pick the best screen by checking your drilling fluid, mesh size, and solids. The right choice saves money and keeps your equipment working well.

Choosing the Right Shale Shaker Screen

Selection Tips

You want to choose the best screens for your drilling job. Start by understanding your drilling operation. Oil and gas wells need different screens than water wells or HDD projects. Look at your drilling fluid. If it is thick or has high gravity, pick a finer mesh screen. For heavy drilling, use screens with more layers. Stainless steel screens work well for tough jobs because they last longer.

Follow these practical tips to get the most out of your screens:

Run your shale shaker all the time during drilling to remove cuttings.

Make sure drilling fluid covers most of the screen. If it does not, your mesh size may be too coarse.

Replace or repair screens right away if you see holes. This keeps solids from bypassing the system.

Prepare new screens and tools before you need them. Change screens during connections to save time.

Keep tensioning parts and vibration isolators in good shape to help screens last longer.

Wash screens at the start of trips to stop fluid from drying and blocking the mesh.

Store screens vertically in a dry place to prevent rust and damage.

Advanced shakers like the Double/Triple Deck Shaker make screen selection easier. These shakers use modular screens that fit many models. You can swap screens quickly without tools. Clear labels show mesh size and performance, so you pick the right screen every time.

Tip: Always match your screen type and mesh size to your drilling fluid and solids. This helps you separate cuttings better and protect your equipment.

Common Mistakes

Many people make mistakes when choosing screens. Avoid these common errors:

Picking the wrong mesh size for your drilling fluid.

Mishandling screens during storage or installation.

Not installing screens correctly on the shaker basket.

Over-tightening or under-tightening screens.

Using screens that are not made well.

Ignoring the condition of the shaker and deck rubbers.

Cleaning screens with high-pressure water, which can damage fine mesh.

Running with heavy solids loading or high mud weight.

You can prevent these mistakes by inspecting screens often, following manufacturer instructions, and keeping all shaker parts in good condition. The Double/Triple Deck Shaker helps you avoid errors by making screen replacement simple and fast.

Knowing about shale shaker screen types helps you drill better. If you pick screens that fit your fluid and shaker, you take out solids faster. This keeps your mud clean. New tools like the Double/Triple Deck Shaker make it easy to use and change screens. These screens last longer and are simple to swap. This saves you time and money.

For the best results, do these things:

Look at your drilling fluid and solid sizes before picking screens.

Choose screens with the right mesh and material for your work.

Check and change screens often so you do not lose time.

Use modular screens to switch fast and work better.

Step | Action |

1 | Check drilling conditions |

2 | Pick mesh size and type |

3 | Care for and check screens |

4 | Use modular shaker systems |

You can talk to Shandong Xilong Machinery Equipment Co., Ltd. for help or advice. They can help you pick the best screens for your drilling job.

FAQ

What is the main job of a shale shaker screen?

A shale shaker screen separates solids from drilling fluid. You keep your mud clean and protect your equipment. Clean mud helps you drill faster and safer.

How do you know which screen type to choose?

You look at your drilling fluid and solids size. You pick a screen with the right mesh and material. You match the screen to your shaker model for best results.

How often should you replace shaker screens?

You check screens every day for damage. You replace screens when you see holes or tears. Quick replacement keeps your drilling job running smoothly.

Can you mix different screen types on one shaker?

You can use different screens on each deck of a modular shaker. Mixing screens helps you separate solids better and handle different drilling conditions.

What makes the Double/Triple Deck Shaker easy to use?

You swap screens fast without tools. The modular design lets you change panels quickly. You save time and keep your drilling site working efficiently.