Choosing the right shale shaker can change your drilling work in 2025. You must match shaker size, screen type, and strength to your site’s needs and goals. Many drilling teams have problems like:

Using the right shaker size for drilling fluid and cuttings.

Picking screen types that last and handle small pieces.

Changing shale shaker picks for different rocks, fluids, and weather.

Thinking about first costs versus saving money and time later.

Using new features like live tracking or parts you can swap.

Making good plans for care to stop work delays.

Choosing strong materials and designs that last long.

Focus on how well it works, how tough it is, how it fits your needs, saving money, easy care, and new tech to pick the best one.

Key Takeaways

Pick a shale shaker that matches your drilling size and fluid. This helps your work stay fast and saves money.

Change vibration settings and choose the best screen mesh. This helps separate solids well and keeps your equipment safe.

Use shakers made from strong materials with screens that are easy to change. This lowers downtime and cuts maintenance costs.

Make sure your shale shaker fits your site’s geology and climate. This gives better results and helps your equipment last longer.

Use new technology like digital monitoring and quick screen changes. This makes drilling faster and safer.

Shale Shaker Role in Drilling Operations

Efficiency and Cost Impact

Shale shakers help your drilling work run well. They are the first machines to take out cuttings from drilling fluids. When you use good solids control equipment, you protect other tools. You also keep your drilling fluid clean.

Shale shakers remove solids early. This keeps the drilling mud thick enough and heavy enough. It helps the well stay strong and lets you control pressure.

Taking out solids fast means less damage to other equipment. You do not need to fix or replace things as often.

Shale shakers let you use drilling fluids again. You spend less money on new mud and do not have to throw away as much waste.

New shale shakers help you finish jobs faster. You do not get slowed down by broken equipment or bad fluid.

Small shale shakers fit in tight spaces. They save room but still work well.

Studies show that the right vibration and screen can make separation better. Some setups can reach 80% classification and 53% dewatering. If you adjust your shale shaker, you get cleaner fluid and drill faster.

Solids Control Importance

Solids control equipment is important for every drilling job. You must keep drilling fluids clean to stop problems and make equipment last longer.

Good solids control equipment takes out unwanted solids from the mud. This keeps the mud safe and easy to use. Clean fluids mean pumps and pipes do not wear out fast. You also lower the chance of equipment breaking and stopping work.

Checking and cleaning your equipment often helps it work well. Keeping good records helps you know when to fix or change parts. This saves money and keeps your drilling work moving.

When you control solids, you help the environment too. You make less waste and stop dirt and water from getting polluted. This helps your business and helps the world.

Shale Shaker Selection Criteria

Capacity and Throughput

You must pick a shale shaker that fits your project size. If the shaker is too small, it cannot process fluid fast enough. This can slow down your work and cause delays. If the shaker is too big, you waste power and spend more money. Most medium drilling jobs use shakers that handle 2.5 to 5 m³/h. Big drilling jobs need shakers that can process 5 to 10 m³/h.

Capacity Category | Capacity Range (bpm) | Capacity Range (m³/h) | Typical Application Scale |

Medium Capacity | 5 - 10 | 2.5 - 5 | Medium-sized drilling projects |

High Capacity | 10 - 20 | 5 - 10 | Large-scale drilling operations |

If you want to drill fast and use lots of fluid, pick a shaker with high capacity. The Double/Triple Deck Shaker from Xilong Machinery can process up to 200 m³/h. This makes it good for tough jobs. These shakers help you get back more liquid and make less waste. You can recover over 95% of liquid and get more than 90% screen effectiveness. This saves you money and keeps your drilling fluid clean.

Vibration and Design

The vibration system is the main part of a shale shaker. Motors shake the screen to separate solids from liquids. You can change how strong the shaking is and the angle of the deck. This helps you get the best results for your drilling fluid. Most shakers have two motors for straight-line motion. Some new shakers use three motors for round or oval motion. More G-force means better separation.

Motors with special shafts make the shaker move.

Vibrating motors shake the basket and help move solids.

You can change how fast and hard the shaker moves.

The angle of the deck helps control how fluid and solids move.

More motors and power make the shaker shake harder.

The Double/Triple Deck Shaker from Xilong Machinery uses a strong motor with up to 8.0 Gs. Its design lets you change screens fast and adjust settings for different jobs. The frame is made from tough aluminum alloy. This makes the shaker last longer and need less fixing.

Adaptability to Drilling Fluids

Drilling fluids can change while you drill. You need a shale shaker that can work with thick or thin fluids. Thick fluids move slow and put more pressure on the screen. Thin fluids move fast and are easier to separate. If your shaker can change how it shakes, it can handle both types of fluids.

Shale shakers can change how much and how fast they shake.

You can match the shaker settings to the fluid’s thickness and weight.

Special parts on the motors help you get the best results.

Stronger shaking at lower speeds works for big, heavy pieces.

Softer shaking at higher speeds works for small, weak pieces.

The Double/Triple Deck Shaker from Xilong Machinery uses sensors to check fluid properties. You can change the speed and shaking in real time. It has a lifting device and air system to help you adjust fast. This makes sure you always get good separation and protect your equipment.

Tip: Always check the pressure and temperature at the bottom of the hole before you pick a shale shaker. Make sure your shaker can handle the fluid and site conditions.

Shaker Screen Technology

Mesh Size and Separation

You must pick the right mesh size for your job. Mesh size decides what solids stay or go with the fluid. Big mesh works best for large cuttings near the top. Small mesh is better for tiny cuttings deep in the well. If you choose the wrong mesh, you may lose drilling fluid. Your equipment could get overloaded too. The right mesh helps you remove solids and keep mud clean. It also protects your pumps.

New shaker screens give you more choices now. Makers use wire mesh, polyurethane, and composite screens. These last longer and separate solids better. Pretensioned screens mean you do not need to tighten them by hand. This gives steady work and longer screen life. Laser-cutting and welding make mesh sizes exact. You get better solids control and drill faster.

Screen Area and Replacement

Screen area shows how much fluid the screen can handle. Bigger screens let you process more fluid at once. This helps your work go faster and smoother. Studies say bigger screen area means more capacity. Pyramid screens and large designs give more mesh surface. This helps you handle more flow and lowers stress on other tools.

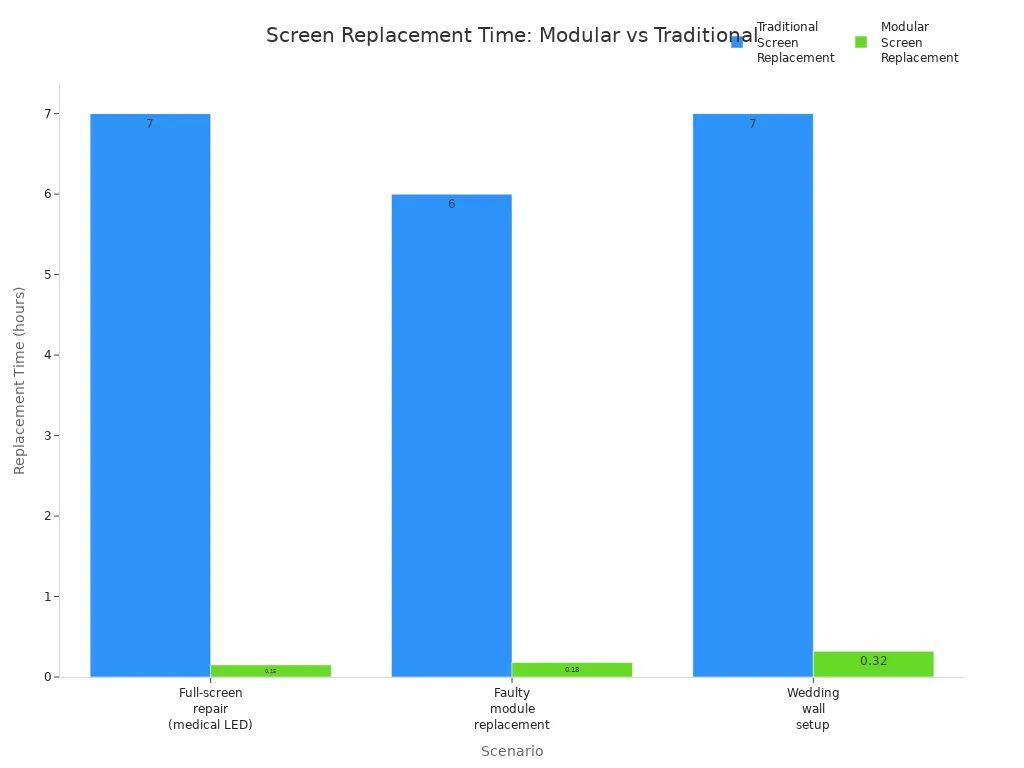

Think about how quickly you can change a screen. Old screens can take hours to swap. This causes downtime and slows work. Modular screens, like Xilong Machinery’s Double/Triple Deck Shaker, let you change screens in minutes. The chart below shows how modular screens save time:

With Xilong Machinery’s quick-change screens, you spend less time fixing things. You get more time drilling. Modular screens are light and easy to move. This keeps your work safe and efficient.

Tip: Always match mesh size and area to your fluid and cuttings. Fast screen changes help your project stay on track and save money.

Performance and Maintenance

Screen Effectiveness

You need to watch some important things to get the best use from your shale shaker. These things help you see how well your shaker removes solids and keeps your drilling fluid clean. Some key things to check are:

Mesh size controls what size particles get caught and stops the screen from getting blocked.

Screen tension keeps the screen flat and stops it from breaking or moving too much.

Conductance shows how easily fluid moves through the screen and helps remove solids.

Screen wear tells you how much the screen gets worn out or tired during use.

You should also check how much fluid and cuttings your shaker handles over time. This is called throughput. Efficiency tells you how well your shaker removes cuttings and keeps the wellbore safe. How often you need to fix or change screens, and how easy it is, affects how well your shaker works. Using sensors and real-time data helps you watch these things and make quick changes for the best results.

Durability and Service Life

It is important for your shale shaker to be strong and last a long time. This helps you save money and avoid stopping work. Strong materials like stainless steel, polyurethane, and composite screens help your shaker work in tough places. These materials do not rust, can take hits, and do not wear out fast. Frames that are made stronger and special ways to join parts help screens last longer, even when they shake a lot or hold heavy loads.

Good screens can last from 104 to 390 hours, depending on where you drill and how you take care of them. Some screens have rubber plugs and many mesh layers to stop damage from spreading. This helps your shaker work well and keeps your maintenance easy.

Maintenance and Downtime

Easy-to-fix designs help your work go smoothly. Shale shakers with modular screens and quick-change parts let you swap things fast. You spend less time fixing and more time drilling. Open designs and systems that do not need tools make cleaning and changing screens simple. This helps you keep downtime low and your shaker working well.

Most unplanned stops happen because screens break, are put in wrong, or are not cared for. Some common problems are screen cloth tearing, rubber seals not working, and blockages. You can stop these problems by cleaning screens when the shaker is off, checking the clamps, and following the maker’s rules. Checking your shaker often and handling it right helps you keep it working its best.

Site Matching and Cost Analysis

Geology and Climate

You must pick a shale shaker that fits your site’s ground and weather. Different rocks and soils can change how well your shaker works. Hard rocks make bigger pieces, while soft rocks make smaller ones. Cold places need equipment that works in low temperatures. Hot places need shakers that do not lose power in heat.

Rocky places need shakers with stronger screens and more shaking power.

Muddy or sandy places do better with bigger screens for better sorting.

Very hot or cold places need shakers with tough motors and strong parts.

The Double/Triple Deck Shaker from Xilong Machinery works from -40°C to 50°C. This means you can drill in many kinds of weather and ground.

Tip: Always check your site’s rocks and weather before picking a shaker. This helps your equipment last longer and work better.

Cost-Benefit and ROI

A good cost check helps you make smart choices. You want to balance the first price with how much you save later. Single deck shakers cost less at first but may not handle big jobs. Double and triple deck shakers cost more because they have bigger motors and more screen space. But these shakers can do the job of many old machines, so you save money over time.

Double deck shakers sort solids better and make drier cuttings.

Triple deck shakers, like Xilong’s, do many jobs in one machine.

Fewer machines mean less fixing and less time stopped.

When you buy good mud cleaning systems, you use less new mud and make less waste. This saves money on mud and trash. New shakers also help you follow rules and avoid fines. Over time, you save energy, your shaker lasts longer, and you fix it less. A careful cost check shows the right shaker helps you get more for your money by working better and cutting hidden costs.

Shaker Type | Initial Cost | Maintenance | Screen Area | System Integration | Long-Term Savings |

Single Deck | Low | Low | Small | Low | Moderate |

Double Deck | Medium | Medium | Medium | Medium | High |

Triple Deck | High | Low | Large | High | Very High |

Note: Always count all costs—buying, using, and fixing—when you check prices. This helps you see what your money really gets you.

Technology Trends for Drilling Mud Shale Shaker

Innovations for 2025

In 2025, drilling mud shale shakers will have many new features. These updates help you work faster and safer. They also help you keep your site clean. More people want shale oil and gas now. New rules mean companies must use better equipment. You need a drilling mud shale shaker that removes solids well and saves water.

High-frequency, multi-deck drilling mud shale shakers can handle more fluid. They separate different sizes of solids in one step.

Modular designs let you move and set up your drilling mud shale shaker easily. You can change it for each job.

Advanced vibration systems help move fluid better. They stop screens from getting blocked.

New screens use strong materials like stainless steel and composite frames. These screens last longer and work in tough places.

Quick-change screen features let you swap screens fast. You spend less time fixing and more time drilling.

Smart technology lets you watch your drilling mud shale shaker from far away. You can see problems before they stop your work.

Sustainable designs use less energy and make less waste. You help the environment and follow new rules.

Some new screens are made with composite and steel frames. They can handle high heat and have pre-tensioned mesh. These features help you work in hard places and keep your drilling mud shale shaker running longer. Automation and real-time monitoring let you control your equipment better. You get more drilling fluid back and make less solid waste.

Digital Integration

Digital integration changes how you use your drilling mud shale shaker. Sensors now watch flow rate, pressure, and solids in real time. You get data sent to a control unit. This helps you make smart choices and change settings fast. You can watch your drilling mud shale shaker from far away. You can fix problems before they get worse.

Smart control systems use PLC interfaces and IoT sensors. You see pressure, flow, and temperature as they happen. This helps you find problems early and plan repairs before things break. You save time and keep your drilling mud shale shaker working well.

IoT systems show you how well your drilling mud shale shaker works. You can check how it runs, plan repairs, and change how you work. In the future, drilling mud shale shakers will use even more digital tools. You will get real-time data and analysis to help you drill smarter and faster.

Tip: Use digital integration to watch your drilling mud shale shaker’s performance. You will find problems early and keep your work going smoothly.

To choose the right shale shaker, follow these steps:

Adjust vibration settings for the best screening.

Pick the right screen angle and mesh size for your drilling needs.

Match the shaker’s structure to your drilling mud.

Balance flow rate and solids removal.

Check supplier support and product quality.

Contact us today to discuss your shale shaker needs and discover how advanced technology can boost your drilling efficiency and ROI.

FAQ

What is a shale shaker used for in drilling?

A shale shaker removes solid pieces from drilling mud. You use it to keep your drilling fluid clean. Clean fluid helps your equipment last longer and makes drilling safer.

How often should you replace shaker screens?

You should check screens daily. Replace them when you see tears, holes, or too much wear. Most screens last between 100 and 1000 hours, depending on your drilling conditions.

Can one shale shaker work for all drilling fluids?

You can use one shaker for many fluids if it has adjustable settings. Change the vibration and screen type to match the fluid’s thickness and the size of the solids.

What should you look for in a shale shaker for cold or hot climates?

Pick a shaker that works in wide temperature ranges. Look for strong motors, tough frames, and screens that resist heat or cold. This helps your shaker run well in any weather.

How does quick screen replacement help your drilling operation?

Quick screen changes reduce downtime. You spend less time fixing and more time drilling. This keeps your project on schedule and saves money.