A shale shaker lets you separate solids from drilling fluid. It uses vibration and screens to do this job. Most drilling sites need this tool to keep fluids clean. It also helps protect other tools from damage.

Metric | Value | Explanation |

Market Share of Shale Shakers in Solid Control Equipment | ~43% | Almost half of solid control equipment are shale shakers. |

Percentage of Land-based Drilling Rigs Using Dual-deck Shale Shakers | >66% | Most land rigs use dual-deck shale shakers for solids control. |

New models, like the Double/Triple Deck Shaker from Shandong Xilong Machinery Equipment Co., Ltd., use better motors and modular screens. These changes help your drilling work run better and cost less.

Key Takeaways

A shale shaker helps clean drilling fluid. It shakes the fluid over screens to take out solids. This saves money and keeps equipment safe.

You can change the screen size, vibration power, and angle. This helps remove more solids and gives you cleaner fluid.

Strong motors and more than one deck make it work better. This lets you clean more fluid and dry solids faster.

Pick shale shakers by looking at the screen type and frame strength. Also check the vibration style, motor safety, and how much it can handle for your job.

Clean and check the screens often. Change the settings and fix problems fast. This keeps your shale shaker working well and stops delays.

Shale Shaker Basics

What Is a Shale Shaker

A shale shaker is used first to clean drilling fluid. It separates big pieces, called cuttings, from the mud. This machine is very important in oil and gas drilling. It shakes the fluid over screens to remove cuttings. The clean fluid can be used again. This saves money because drilling fluid costs a lot.

A shale shaker has a hopper, screen basket, vibrator, feeder, and a basket angling part. The screens use API screen numbers to pick the right size. Using a shale shaker keeps your equipment safe. It also helps your drilling work go well.

Tip: Pick the right screen size to get rid of the right particles and keep your drilling fluid clean.

The main jobs of a shale shaker in the drilling fluid system are:

Function | Description | Purpose/Benefit |

Effective Solids Control | It separates big and small solids from drilling fluid with vibrating screens. | It stops solids from causing problems and keeps tools safe. |

Enhanced Drilling Fluid Properties | It takes out solid bits to make the fluid work better and reduce friction. | This helps drill faster and saves money by making drilling easier. |

Protection of Downhole Equipment | It removes hard solids early so they do not hurt pumps and other tools. | This makes equipment last longer and cuts down on repairs. |

Environmental Compliance and Waste Management | It takes out solids so you can reuse fluid and throw away waste the right way. | This follows rules and helps protect the environment. |

Versatility and Adaptability | You can change the screen angle and vibration to fit different drilling jobs. | This helps the shale shaker work well for many types of wells and fluids. |

How It Works

Drilling fluid comes up with cuttings and solids. You pour this fluid onto the shale shaker. The machine shakes the fluid over the screens. The screens act like a filter. Big solids stay on top. Clean fluid goes through and into mud tanks.

The vibration makes three areas on the screen: drainage, drying, and beach. Each area helps separate fluid and solids in its own way. The shaking sorts particles by size and weight. Small bits and fluid go through the holes. Big pieces stay on top. You can change the shaking strength and screen angle for your job.

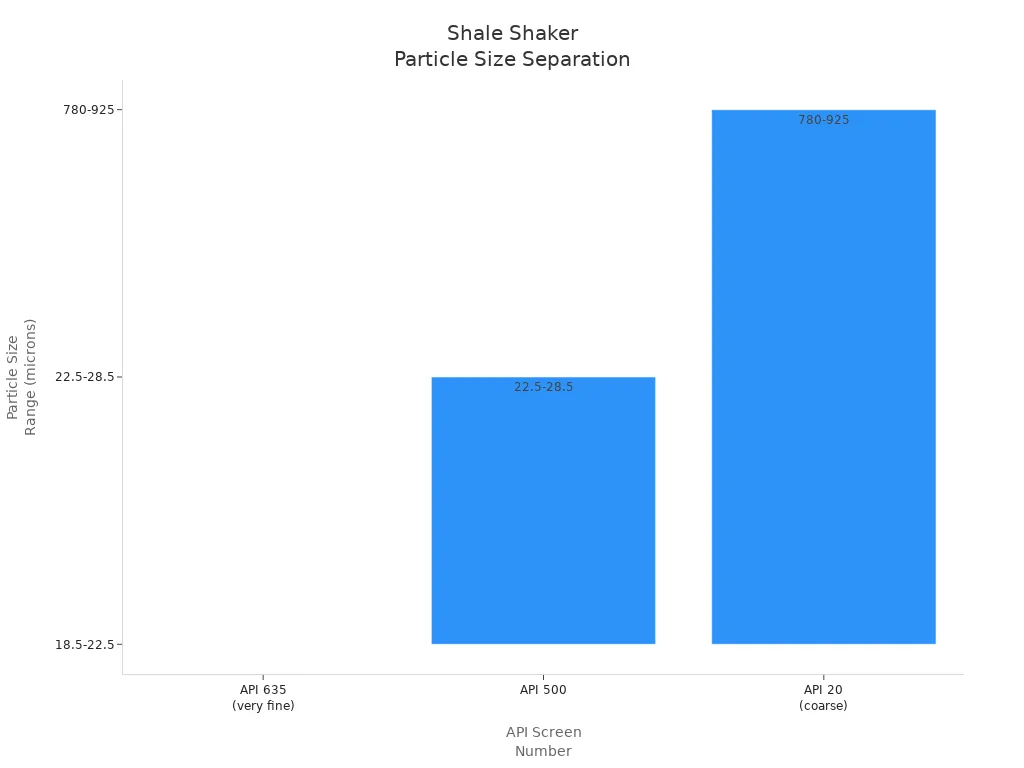

The screen mesh decides what size particles the shale shaker can remove. Most shakers take out particles from about 20 microns to 1000 microns. The chart below shows how API screen numbers match with particle sizes:

You get the best results by balancing shaking strength, screen slope, and screen size. This helps you remove solids fast, keep screens working longer, and get more clean fluid. The shale shaker protects pumps and other tools by stopping big solids early.

Note: Using your shale shaker the right way stops blockages and keeps your drilling fluid working well.

Shale Shaker Components

Vibrating Motor

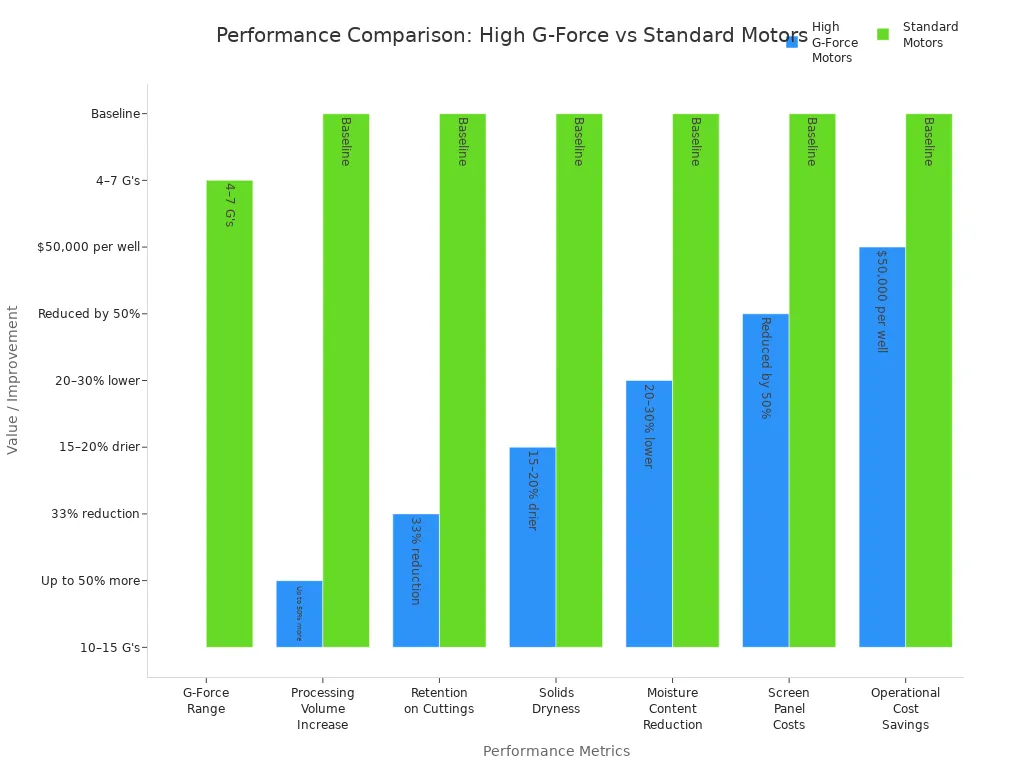

The vibrating motor is very important in a shale shaker. It makes the machine shake and helps separate solids from the drilling fluid. High G-force motors can shake much harder than regular ones. They can reach up to 10–15 G's, while standard motors only reach 4–7 G's. This strong shaking moves more solids across the screens and dries them better. You can process up to 50% more fluid with these motors. The screens also last longer. The table below shows how high G-force motors do better than standard motors:

Feature/Metric | High G-Force Motors | Standard Motors |

G-Force Range | 10–15 G's | 4–7 G's |

Processing Volume | Up to 50% more | Baseline |

Solids Dryness | 15–20% drier | Baseline |

Screen Panel Costs | 50% lower | Baseline |

You can change how strong and fast the shaker moves. This helps you match the machine to your drilling job. It also helps the parts last longer.

Screen Panels

Screen panels catch solids from the drilling fluid. You can pick different mesh sizes for the screens. Smaller mesh holes catch tiny solids but slow down the fluid. Bigger mesh holes let more fluid pass but may miss small solids. Most screens are made from stainless steel or polyurethane. These materials make the screens strong and last longer. The API screen number system helps you choose the right screen. This lets you balance how many solids you remove and how much fluid you keep.

Basket and Deck

The basket and deck hold the screens in place. They also help the shaker move. A strong and modular design lets you add more decks if you need them. You do not have to buy a whole new machine. This makes the shaker last longer and work better. The basket design lets you change screens easily. Hydraulic lifts and automatic angle controls save you time when fixing the machine. You can handle more fluid and get drier solids. This helps you spend less on getting rid of waste.

Control System

Modern shale shakers use smart control systems. Sensors watch the vibration, screen health, and fluid flow all the time. You can change settings like how hard the shaker moves or the angle of the screen. The controls are easy to use. Pneumatic systems let you change screens quickly and safely. Sometimes you only need to press a button. These features help your work go smoothly. They also make the job safer and reduce time lost to repairs.

Shale Shaker Operation

Vibration Process

You use the vibration process to move solids on the screens. The shaker has a motor that makes it shake fast. This shaking helps take solids out of the drilling fluid. You can change how fast and strong the shaker moves. If you use faster shaking, more solids move and dry quicker. The table below shows how different settings change how well the shaker works:

Parameter | Typical Range / Value | Effect on Solids Conveyance and Capacity |

Frequency | 20 Hz to 60 Hz | Higher frequency increases capacity up to a point; too high can lower efficiency. |

Acceleration (g-force) | Around 4g | More g-force means more capacity, but only up to a certain level. |

Amplitude | Variable | More amplitude improves mud flow and reduces trapped fluid. |

Deck Angle | 15° to 33° | Angle affects how solids move and how much screen area you use. |

If you make the shaker move more, less fluid gets stuck. This gives you drier solids and better separation.

Solids Separation

The screens catch solids as the fluid moves over them. The type of screen you use is important. Steel screens are strong and last a long time. Polyurethane screens do not break easily and are simple to fix. Composite screens are tough and do not rust. Some screens have pyramid shapes. These give you more space to catch solids. You can remove more solids with these screens. Mesh size is also important. Smaller mesh catches tiny pieces, but slows down the fluid.

Steel screens: strong and last long

Polyurethane screens: hard to break and easy to fix

Composite screens: very strong and big area

You need to keep the screens tight and check them often. This helps the shaker work well.

Fluid Recovery

You want to get back as much clean fluid as you can. The shaker lets fluid go through the screens. Solids stay on top of the screens. You can change how the shaker moves and the angle of the screens. This helps you get more fluid back. Stronger shaking and the right mesh size leave less fluid in the solids. This saves money and keeps drilling going well. New shakers let you change settings fast. You can match the shaker to your drilling job and get the best results.

Types and Selection

Single, Double, and Triple Deck

You can pick single, double, or triple deck designs. Single deck units have one screen layer. These are good for simple jobs and small drilling sites. Double deck shakers have two screen layers. The top catches big solids. The bottom takes out smaller bits. This gives you more screen space and lets you clean more fluid at once. Triple deck shakers use three layers with different mesh sizes. You get several steps of separation in one small machine. This design can replace extra equipment. It saves space and lowers costs.

Double and triple deck models have special features. You might see hydraulic tilt, airbag screen pressing, and better vibration controls. These make the shaker easier to use and help you change screens fast. Multi-deck shakers work with faster drilling and more solids. You can clean more fluid without needing bigger machines.

Multi-deck and modular designs help you work in many drilling conditions. You can drill faster and stop less by making solids control better.

Choosing the Right Shale Shaker

You should think about a few things when picking a unit:

Screen Mesh Size and Type: Pick mesh size for the solids you want gone. Pyramid and composite screens give more area and last longer.

Frame Material: Use strong steel or composite frames for long life.

Vibration Mode: Linear motion is best for lots of solids. Balanced elliptical motion is softer and helps screens last.

Motor Configuration: Explosion-proof motors and variable drives let you change vibration and stay safe.

Processing Capacity: Make sure the unit can handle your fluid amount.

Certifications: Look for IEC, UL, ATEX, and CE for safety and rules.

Integration: The unit should fit your rig and be easy to fix.

Selection Criteria | Why It Matters |

Screen Mesh Size | Controls what particles you remove |

Frame Material | Makes the unit last longer |

Vibration Mode | Changes how well it works and screen life |

Motor Configuration | Keeps things safe and flexible |

Processing Capacity | Matches your drilling needs |

Certifications | Follows safety and industry rules |

Integration | Makes work and repairs easier |

Tip: Always pick a unit that matches your drilling job and fluid type. This helps you get the best results and save money.

Maintenance and Troubleshooting

Routine Maintenance

You must keep your equipment in good shape for best results. Here are some easy steps for routine maintenance:

Look at the screens often and clean them to stop blockages.

Check screens for holes or tears. Change them if you find damage.

Change vibration, angle, and speed to fit your drilling job. This helps screens last longer.

Make a plan for regular screen changes, safe storage, and gentle handling.

Run the equipment hard enough to remove solids, but not so hard that screens wear out fast.

Tip: Clean screens after each use and keep them dry. This makes them last longer and work better.

Common Issues

You might have some problems when using the equipment:

Sticky shales can block screens, mostly with water-based mud. Some shales swell when they touch water.

The drive shaft may stop turning if bearings break, belts are loose, or the outrigger is damaged.

Screens can clog if there is too much fluid, thick mud, fine mesh, or stringy stuff.

Mechanical problems like blockages or broken bearings can stop the machine.

Electrical problems can happen if the power is not steady or voltage changes.

Very hot, cold, or dusty places can make the equipment work poorly.

Using the wrong settings or making mistakes can also cause trouble.

Troubleshooting Tips

You can fix most problems by doing these things:

Pick the right screen mesh and material to stop blinding.

Use cleaning tools, like air or machines, to keep screens clear.

Change vibration and angle to move solids better and stop clogs.

Watch the fluid and keep it in the right range.

Check and take care of all parts, like motors, tension systems, and seals.

Use real-time monitors if you have them to find problems early.

Checking your equipment often and fixing problems fast helps you avoid long stops and keeps your equipment working longer.

Picking the right equipment helps drilling work go well. New technology lets you get back more fluid and spend less money. If you use and care for your tools the right way, they last longer and work better. To make solids control better, try using advanced tools like the Double/Triple Deck Shaker. You can talk to Shandong Xilong Machinery Equipment Co., Ltd. if you want to learn more or do business with them.

FAQ

What does a shale shaker do in drilling?

A shale shaker separates solids from drilling fluid. You use it to keep the fluid clean. This helps your drilling equipment last longer and work better.

How often should you replace shale shaker screens?

You should check screens daily. Replace them when you see holes, tears, or reduced performance. Regular checks help you avoid downtime and keep your operation running smoothly.

Can you adjust the vibration settings on a shale shaker?

Yes, you can change vibration strength and speed. Adjust these settings to match your drilling needs. This helps you get better solids separation and longer screen life.

What safety features should you look for in a shale shaker?

Look for explosion-proof motors, easy-access controls, and certified components. These features help you work safely and meet industry standards.

How do you clean and maintain a shale shaker?

Clean screens after each use. Check motors, seals, and tension systems often. Follow a maintenance schedule to keep your shale shaker working well and avoid costly repairs.