Oil extraction is a complex and precise process that requires the use of various mechanical systems to extract crude oil from deep within the earth. Among the many methods used to bring oil to the surface, the sucker rod pump is one of the most widely used and effective techniques, especially in wells with lower pressure. This mechanical pumping system has been a staple in the oil and gas industry for over a century due to its proven reliability and efficiency.

In this article, we will explore the mechanics behind sucker rod pumps, how they work, their components, and the role they play in modern oil extraction. Additionally, we will look at how the proper understanding and maintenance of these systems can improve productivity in oil fields.

1. What Is a Sucker Rod Pump?

A sucker rod pump, also known as an artificial lift system, is used to extract oil from wells that do not have enough natural pressure to bring the oil to the surface. It is an efficient mechanical system designed to lift crude oil from the reservoir to the surface by using a pump jack, sucker rods, and a downhole pump.

The pump jack generates mechanical energy that is transferred through the sucker rods to the downhole pump. The downhole pump, located at the bottom of the well, is responsible for lifting the oil to the surface. The design of the sucker rod pump is simple yet highly effective, making it a reliable option for oil operators working in low-pressure wells.

2. How Does a Sucker Rod Pump Work?

The operation of a sucker rod pump is based on a simple principle: the up-and-down motion of the pump jack is transmitted through the sucker rods to the downhole pump, which extracts oil from the well. Let’s break down the mechanics of how this system works:

a) Pump Jack (Surface Unit)

The pump jack is the mechanical device located at the surface of the well. It is also called a walking beam and is powered by an electric motor or an engine. The pump jack creates the up-and-down motion needed to operate the system.

Upward Motion: As the pump jack moves upward, it pulls the sucker rods (a series of long metal rods) attached to the pump.

Downward Motion: When the pump jack moves downward, the sucker rods are pushed down, applying pressure to the downhole pump and moving oil upward.

The pump jack is the driving force behind the entire operation, converting mechanical energy from the motor into the motion needed to lift oil from the well.

b) Sucker Rods

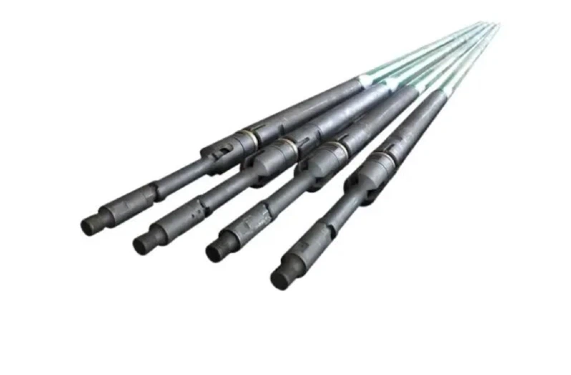

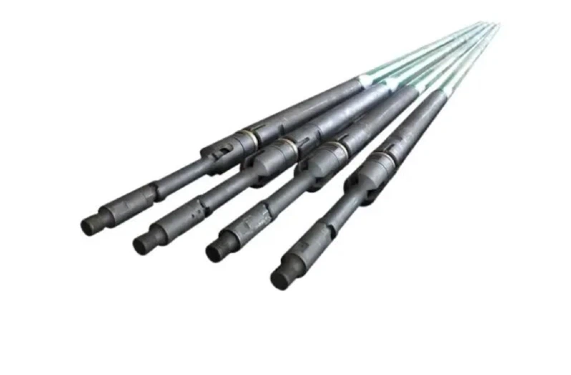

The sucker rods are the long, metal rods that connect the pump jack to the downhole pump. These rods are the essential components that transfer the mechanical motion from the surface equipment to the pump at the bottom of the well.

The rods are usually made of high-strength steel, but they can be made from various materials depending on the well conditions. These rods must be strong enough to handle the stress and strain of the continuous motion, and they are designed to endure friction and wear.

c) Downhole Pump

At the bottom of the well, the downhole pump is responsible for lifting the oil to the surface. The pump consists of several key components:

Plunger: The plunger moves inside the pump barrel to create a vacuum that draws oil into the pump chamber.

Valves: The downhole pump uses check valves to control the flow of oil. There are typically two types of valves: the suction valve (located at the bottom of the pump) and the discharge valve (located at the top). These valves ensure that oil moves in the correct direction—up to the surface.

Barrel: The barrel is the casing that contains the plunger and valves. It is designed to maintain pressure and prevent oil from leaking out.

The motion of the sucker rods moves the plunger inside the barrel, creating a suction that draws oil into the pump. As the pump jack moves downward, the plunger is forced down, pushing the oil upwards toward the surface. This process continues in a repetitive cycle.

d) Energy Transfer and Fluid Movement

The mechanical energy generated by the pump jack is transferred through the sucker rods to the plunger in the downhole pump. When the plunger moves upward, it creates a vacuum that draws oil into the pump chamber. As the plunger moves downward, it forces the oil upward toward the surface.

The process of lifting the oil to the surface relies on the combination of mechanical energy, fluid pressure, and the effective sealing of the pump valves. The sucker rod pump creates a continuous flow of oil from the reservoir to the surface, as long as the pump is properly maintained and operated.

![333 (2) 333 (2)]()

3. Key Components of a Sucker Rod Pump System

Understanding the mechanics of the sucker rod pump system requires a closer look at its individual components. Each part plays a critical role in the overall functioning of the pump.

a) Pump Jack (Walking Beam)

The pump jack is the surface equipment that provides the necessary motion to operate the sucker rod pump. It consists of several components:

Beam: The long, horizontal beam that moves up and down.

Crank: The crank mechanism connects the beam to the motor, providing the rotational motion needed for the up-and-down movement.

Pulley System: A set of pulleys guides the motion of the sucker rods, ensuring smooth movement.

Motor/Drive System: The motor or engine powers the pump jack. It can be an electric motor, diesel engine, or even a solar-powered system in remote locations.

The motor generates the mechanical energy that is transferred to the sucker rods through the pump jack’s movement.

b) Sucker Rods

Sucker rods are a series of long, steel rods that connect the pump jack to the downhole pump. They are the transmission mechanism that carries the mechanical energy from the surface to the pump at the bottom of the well.

Sucker rods can vary in length and diameter depending on the depth of the well and the required lifting capacity. They are designed to be durable and resistant to wear and corrosion.

c) Downhole Pump

The downhole pump is located at the bottom of the well and is responsible for lifting the oil to the surface. The main parts of the downhole pump are:

Plunger: Moves up and down inside the barrel, creating suction to draw oil into the pump.

Suction Valve: Controls the flow of oil into the pump.

Discharge Valve: Controls the flow of oil out of the pump, directing it upward to the surface.

Pump Barrel: The casing that contains the plunger and valves.

The downhole pump is sealed to maintain pressure, ensuring that the oil flows efficiently without leaking out of the system.

d) Valves

The suction valve and discharge valve control the flow of oil into and out of the downhole pump. These valves open and close based on the motion of the plunger. The suction valve allows oil to enter the pump during the upward stroke of the plunger, while the discharge valve releases the oil during the downward stroke.

4. Benefits of Sucker Rod Pumps in Oil Fields

Sucker rod pumps are widely used in oil fields due to their numerous benefits. Some of the key advantages include:

a) Cost-Effective

Sucker rod pumps are generally more affordable to install and maintain than other artificial lift methods such as electric submersible pumps (ESPs) or gas lift systems. The initial cost of the equipment and ongoing maintenance expenses are lower, making them an attractive option for operators looking to reduce operational costs.

b) Reliability

Sucker rod pumps have been in use for over a century and have proven to be highly reliable in a wide range of oil field conditions. Their mechanical simplicity makes them easier to maintain, and they can operate for long periods without failure, provided they are properly maintained.

c) Efficient in Low-Pressure Wells

Sucker rod pumps are particularly effective in low-pressure wells, where natural reservoir pressure is insufficient to bring oil to the surface. By using the mechanical motion of the pump jack, sucker rod pumps can lift oil from these wells, ensuring consistent production.

d) Durability and Long Life

The robust design of sucker rod pumps ensures that they last for many years. Regular maintenance, such as lubricating the rods and replacing worn-out components, can extend the lifespan of the pump, making it a long-term solution for oil operators.

5. Conclusion

Sucker rod pumps are an essential part of oil extraction in fields where the natural pressure is insufficient to push oil to the surface. The system relies on a simple yet effective design: a pump jack, sucker rods, and a downhole pump work together to lift oil from the reservoir to the surface. This process is reliable, cost-effective, and efficient, making sucker rod pumps one of the most widely used methods for artificial lift in the oil and gas industry.

Proper understanding of the mechanics behind sucker rod pumps is essential for oil operators to ensure the system functions efficiently and reliably. By focusing on regular maintenance, correct installation, and selecting high-quality components, oil operators can maximize the performance of their sucker rod pumps.

As an industry leader in manufacturing equipment for oil extraction, Shandong Xilong Machinery Equipment Co., Ltd. provides top-notch sucker rod pumps and other oil field equipment designed to meet the demands of modern oil production. With a commitment to quality and innovation, Shandong Xilong continues to support the oil and gas industry with reliable and efficient solutions for oil extraction.